When thinking of an optical fiber, one usually imagines the thin strands of glass that extend for thousands of kilometers around the globe forming the backbone for optical communications networks and the internet. A wide range of other devices, from fiber lasers to sensors, also benefit from extending optical functionalities along the length of a fiber. In terms of the form factor, there could be nothing more remote from an extended fiber than a nanoparticle. Such nanoparticles are typically produced via chemical synthesis, and a new route must be established for each new material.

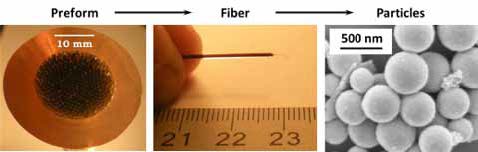

In 2012, Professor Abouraddy’s group reported in the journal Nature the first observation of a fluid instability within a fiber formed of multiple materials. The same physical mechanism that make faucets drip is thermally induced inside a fiber – and if the core and cladding materials are chosen appropriately, the continuous cylindrical core can be made to break up into a necklace of spheres held stationary and isolated from each other within the cladding matrix. Surprisingly, this fluid instability operates at both the macroscopic and microscopic scales, leading to the controllable fabrication of uniformly sized glass spheres that are big enough to be visible to the naked eye, down to 20-nm particles – the size of a single virus.

The past year witnessed two new breakthroughs based on the original observation. First, Abouraddy’s group at CREOL in collaboration with Prof. Ratna Chakrabarti’s group at UCF’s Burnett School of Biomedical Sciences, College of Medicine, confirmed that this particle fabrication process is independent of chemistry by utilizing a wide range of polymers – even the polymer ABS (acrylonitrile butadiene styrene) used in making LEGOs® was drawn into a fiber that yielded particles upon thermal treatment! By using biocompatible polymers, microparticles were produced and then employed in biosensing experiments. Furthermore, a hollow fiber was used to create polymeric micro-capsules filled with a biological cargo (collagen was used here) that was later released. These results were published in the Proceedings of the National Academy of Science, the first paper from CREOL published in this prestigious journal. The partnership between the two colleges is UCF’s latest step in fostering collaborative research projects that will have improved chances for federal funding. The joint UCF project is called RIBOP – Research Initiative In Biophotonics – and was initiated after both colleges and the UCF Office of Research and Commercialization each contributed $15,000 to identify biological applications for photonics and lasers.

A second breakthrough was achieved in collaboration with Prof. Yoel Fink’s group at MIT in which the reach of this in-fiber fluid instability process is extended to new temperature regimes and types of materials. Specifically, a silica-cladded silicon-core fiber is continuously fed into a flame defining an axial thermal gradient to continuously form spheres whose size is controlled by the feed speed to <500 nm. Moreover, a fiber with dual cores (p-type and n-type silicon) is drawn and processed into spheres. The separation between the two cores was chosen to induce spatially coherent breakup in the two cores leading to the joining of the spheres into bispherical silicon ‘p–n molecules’. Indeed, measurements reveal a rectifying I–V curve consistent with the formation of a p–n junction. A paper entitled “Silicon-in-silica spheres via axial thermal gradient in-fiber capillary instabilities” was published in Nature Communications describing these results.

Prof. Abouraddy’s group is currently extending the capabilities of this process further by endowing the nanoparticles produced with optical and magnetic functionalities, in addition to adopting the use of biodegradable polymers. In collaboration with Prof. Chakrabarti’s group, the first experiments on selective drug delivery to cancer cells are currently underway.