In recent years, the increasing penetration of flexible devices into the consumer products market has led to a surge of interest in flexible photonics, i.e., integrated optical systems fabricated on flexible polymer substrates that can be mechanically deformed without compromising their optical performance. In addition to being an essential component in consumer electronics, flexible photonics also have enormous application potential for board-to-board optical interconnects, epidermal sensors, wearable photonics and flexible displays as well as other arenas where light-weight, compact optical function is required.

To date, most flexible photonic devices are made entirely from polymers. Unfortunately, polymer-based systems generally have small refractive index differences between their cores and claddings, resulting in weak light confinement, a large device footprint, excessive loss during bending and limited thermal stability. These attributes can affect and limit device design, processing, and integration strategies. Highindex-contrast semiconductor photonic devices can be alternatively fabricated using pattern transfer to overcome these limitations. However, the transfer process is complicated and has limited integration capacity. Further, the resulting devices only exhibit moderate flexibility with a bending radius typically no less than 5 mm.

Chalcogenide glass, specifically, oxygen-free glasses that transmit throughout the infrared, have seen increasing use in a diverse range of infrared optical system. CREOL’s Glass Processing and Characterization Laboratory, led by Prof. Kathleen Richardson, designs and manufactures glasses with tailored optical and physical properties that are compatible with a range of platforms that span bulk molded optics, planar integrated photonics and optical fibers. In work published in the June 2014 issue of Nature Photonics the Richardson team partnered with Prof. Juejun Hu’s group at the University of Delaware and CREOL/UCF spin-off IRradiance Glass to develop glasses compatible with polymer substrates for use as flexible, infrared photonic structures. The flexible photonic chip boasts excellent optical performance and extreme mechanical robustness and flexibility enabling repeated bending down to sub-millimeter radius without measurable performance degradation. Both of these advances represent major improvements over other state-of-the-art devices.

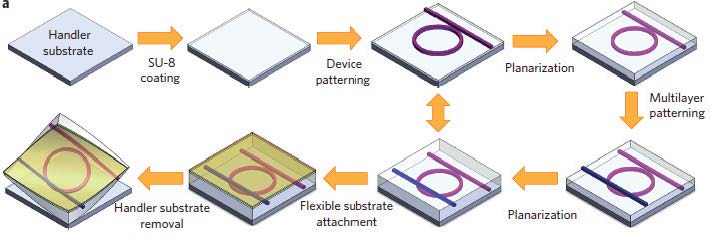

Designing requisite optical function with the mechanical and chemical compatibility needed to engineer device robustness, the team blended optical material science expertise to realize an integrated flexible chalcogenide glass photonic device. The device’s performance enhancement capitalizes on two innovations. First is the adoption of highindex chalcogenide glasses (ChGs), namely the amorphous compounds of S, Se or Te as the backbone optical materials. Unlike oxide glasses, chalcogenides can be deposited at room temperature without compromising their low loss properties, thus facilitating monolithic photonic integration on plastic substrates. Second, a novel multi-neutralaxis micro-mechanical design is implemented to render the structure highly flexible. In the design, a soft silicone adhesive layer is sandwiched inside the flexible substrate, which serves to significantly relieve the strain in the composite structure. This design allows the photonic layer to be placed close to the surface, enabling access to the optical field for applications such as sensing.

Critical to the optical and mechanical design was use of a solution derived processing route that allows conformal glass films of single or varying composition, to be integrated with desired low optical loss in a manner compatible with multi-material property and processing windows. The UCF/UD team’s monolithic integration route offers excellent device performance with high yield: their best optical resonator device exhibited an intrinsic Q-factor as high as 460,000, which is believed to be the highest value reported in photonic devices on plastic substrates. Even after the membrane was bent many thousands of times at 0.8 mm bending radius, the devices maintain structural integrity and only a small increase (0.5 dB cm–1) in optical losses. These results open up emerging application avenues of flexible photonic devices where they can benefit from superior optical and mechanical performance extending from traditional substrates to alternatives for use in land- and space-based application arenas.

Similar strategies are currently in use in other multi-material, planar integration efforts taking place at CREOL between the GPCL team in partnership with Profs. Fathpour and Kuebler. Additionally, as part of a Delaware/UCF US Dept. of Energy SunShot Transformational Photovoltaic Science and Technology Program, ChG films are being examined in enhanced light capture strategies employing asymmetric gratings imprinted on solar cells.

Prof. Richardson is currently serving as President of the American Ceramics Society (ACerS) and she is past-President of the National Institute of Ceramic Engineers.

This summary was adapted from highlights reported in OSA’s Optics and Photonics, 1 December 2014

Author