Chalcogenide glass (ChG) – based optical materials that transmit throughout the infrared (IR) have seen increasing use in a diverse range of infrared optical system. In recent years, traditional IR optical systems for the mid-wave infrared (MWIR) and long-wave infrared (LWIR) based solely on ZnS and ZnSe, Si, Ge, and other semiconductor crystalline materials have progressed towards integration with infrared glass and glass ceramic materials. The growth in their use is a result of greater production (by commercial glass manufacturers) and improvements in the know-how of the optics manufacturing protocols (by optics fabrication houses). Such expansion requires investment and training as the expansion of fabrication methods beyond oxide materials requires the optician to not only handle the unique thermal- mechanical properties of new materials but attention to disposal protocols of waste from these non-oxide materials. Unlike oxide optical materials, IR optical manufacturing requires dedicated facilities that prevent cross-contamination, as oxide impurities can dramatically reduce IR transmissivity in important spectral regimes.

Bulk ChG optics have been integrated into existing airborne imaging systems and are being explored for use as bulk replacements for legacy crystalline (Ge) optics in newer broadband systems, as windows, domes and other free space optical components. Additionally, new physical and solution-based deposition techniques for ChGs developed by Prof. Kathleen Richardson’s team and others enable use of ChGs as waveguides, resonators and other micro-optical components compatible with integration processes in next- generation planar photonics on Si, flexible polymers and most recently, on Graphene. These advances enable ‘ChG microphotonics’ [reported by Richardson’s group in CREOL’s 2015 Annual Report].

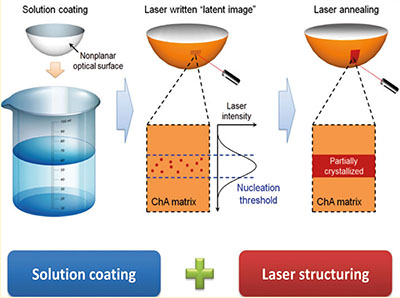

Recently, these activities have been extended to include development of new multi- component, multi-phase chalcogenide alloys (ChAs) which can be glassy or crystalline, as low-loss alternatives to GeSbTe phase change materials (PCMs). ChAs are envisioned as being low-loss (across the defined IR band(s) of use), electrically- or optically-activated PCMs when integrated onto fixed (solid) or flexible substrates, as depicted below. These activities are currently being supported at UCF through a multi-disciplinary effort as part of DARPA’s EXTREME program. The program aims to develop materials and platforms that enable ‘tunable’ structures based on amorphous, α, crystalline, c, or tailored intermediate multi- phase (α + c) materials for a wide variety of applications. While ambitious, the materials and material integration work to realize such goals, shows promise towards the design and fabrication of new material strategies that will enable multi-spectral imaging systems. The figure below illustrates the processing strategy employing solution-derived ChA and their direct application onto a conformal surface followed by the spatially-controlled formation of secondary crystalline phase, which locally induces a change in optical function.

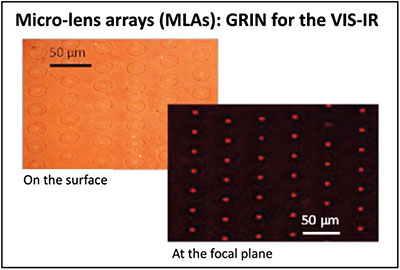

CREOL’s Glass Processing & Characterization Laboratory research team, led by Prof. Richardson, works on translating ideas as to how these novel infrared optical materials (in their amorphous, crystalline or their ‘multi-phase: glass + crystalline’ glass-ceramic (GC) form) can be integrated into novel designs to add new functionality to multi-material systems. Benefiting from industry, government and academic institutional support, her team and collaborators have recently developed a suite of materials and processing methodologies that translate unique optical function onto a range of platforms to yield homogeneous or gradient refractive index (GRIN) behavior with tailorable properties. These materials include ChG or visible diffractive or refractive GRIN components created by thermal poling, chalcogenide GRIN nanocomposites realized by spatially-defined nucleation and growth of a secondary high-index phase in a low-index matrix, ChG-based multi-layer GRIN structures from 3D printed glass layers and laser- written gradient ChG meta-lens structures exploiting laser-induced etch selectivity of the chalcogenide glass films. Details on these findings are summarized in publications on Dr. Richardson’s website.

Highlighting one of these examples is the material chemistry optimization to realize stable, long-lived index modification in post- poled ChG micro-lens arrays (MLA’s) depicted in the upper right image. Shown (left) is the surface topography of the lenslet array (with RMS surface roughness < 100 nm) and the resulting image (right) at the lenslet’s focal plane. Here, the shape and magnitude of the gradient refractive index profile, and the resulting MLA’s focal length created in the glass’ near-surface layer can be tailored by controlling the size and shape of the transparent electrode pattern used to induce the field. The optical stability of the resulting post-poled structure results not realized in prior efforts on ChGs, arises from the engineering of the glass’ network which restricts the mobile ion’s (Na+) ability to relax upon removal of the applied field. This patented work, developed as part of a dual PhD project by UCF–Univ. Bordeaux MSE student Dr. Antoine Lepicard, is being evaluated for technology transfer with the Aquitaine Science and Technology office (AST) and UCF.

The common denominator of each of these efforts, is the need for compositional design that addresses not only the spectral window and target optical properties (i.e., refractive index, dispersion, dn/dT) of the materials, but also the manufacturing-related property optimization (hardness, toughness, coefficient of thermal expansion (CTE) and environmental stability (i.e., to moisture or radiation)) needed for the optical component or system they will be integrated into. Beyond these baseline material attributes, is the knowledge towards creating the single- (glass) or multi-phase (glass + crystal) composite’s behavior and the underlying material science of how such phase formation and stability behavior impacts the component’s absorption, scattering or if appropriate, nonlinear optical property performance as-fabricated, and over time.

With this know-how, and ongoing evidence of successful integration into planar or bulk optical components and systems, further advancement into novel material development can lead to advances in optical functionality not previously observed in homogeneous, single phase optical materials.

For more information, on these and other examples of infrared material and process methodology optimization for IR components, see publications and patents listed on CREOL’s website.